Extraction & Venting

Over Pressure Venting & Post Fire Extraction

It is important that correctly designed, and engineered, Over Pressure Vents (OPV) are fitted within enclosures protected by a gaseous suppression system. This is to prevent the possibility of the structural integrity of the area failing.

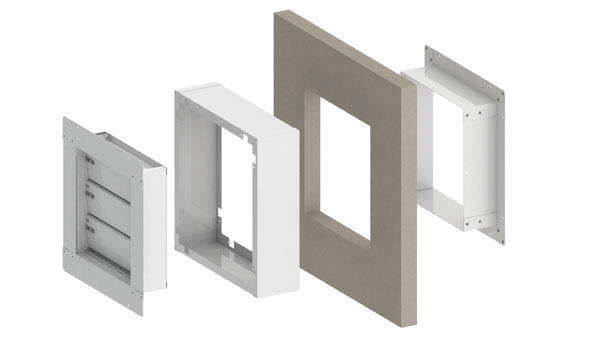

Over Pressure Venting

Ventilation allows for pressure relief within a room during a discharge.

It is important that correctly designed, and engineered, Over Pressure Vents (OPV) are fitted within enclosures protected by a gaseous suppression system. This is to prevent the possibility of the structural integrity of the area failing.

This is particularly important in areas that have boundaries constructed in anything else other than blockwork, although these too can be affected by structural stress derived from high pressure-induced forces produced within an area during a discharge.

1. Gravity Vents:

The blades within these vents are generally hinged on the top edge. They have no electric or pneumatic actuation but rely totally on the room pressure change to move the vent blades. This type of vent may provide a free vent area (the effective area provided by the vent when subjected to the required pressure at the peak flow rate) that is significantly less than the gross vent area (the overall area of the vent). Vents, if not fitted with a stop, could relieve pressures in both directions. However, these are not recommended unless they are able to avoid compromising the enclosure’s fire rating.

2. Counter weighted vent:

This type of vent is configured with the hinge located just off the centre of gravity, so that when positive pressure is exerted on the upstream side of the vent, it allows the vent blades to pivot to their fully open positions. The vent can be designed in such a way that there is a minimum operational release pressure, which will ensure that nuisance movement is avoided. Typically, these vents are more efficient than gravity flap vents.

3. Electrically operated vents:

This type of vent consists of blade(s) operated by an electric motor. This type of vent is reliant upon power at the time of the discharge, therefore if no other option is available there should be a protected power supply (PPS) to the vent motor to ensure that failure of the mains does not leave the vent inoperable. This type of vent generally opens more slowly than all the other types of vents, and correct operation can be dependent on the sequence of activation and the time allowed for the vent to open fully.

4. Pneumatically operated vents:

Pneumatically operated vents are actuated by air pressure. These are normally connected, via tubing, to the main system’s pipework which in turn, feeds pressurised ‘air’ to the vent when the system activates. Alternatively, vents can be activated by pilot cylinders connected as part of the main system or a controlled compressed air-line. These vents are very efficient, as they are controlled by the system’s pressure itself during discharge and have no nuisance movement. This makes them ideal for offshore installations, or other areas with adverse weather conditions

How OPV relates to Inert or Synthetic Gas

Inert gaseous agents can produce very high positive peak pressures (the maximum specified differential pressure in the enclosure used for design of the vent system. This must not exceed the room strength), but no negative peak pressures.

Synthetic agents on the other hand, produce low positive peak pressures but can produce high negative peak pressures.

As a guideline only and based on our understanding of building strength standards within the UK, a normal (blockwork) wall can withstand a pressure of up to 500 pascals. A lightweight wall, such as a studded wall, can withstand a pressure of up to 250 pascals. Inert gaseous agents, upon deployment, can generate positive peak pressures in excess of 1500 pascals, and synthetic gaseous agents can produce negative peak pressures in excess of 400 pascals, so it is clear that pressure venting is an important consideration during the system design phase.

Despite many beliefs on negative pressure venting for synthetic gaseous agents not being required, BS EN 15004-1:2008, Section 7.4, clearly states that “Venting shall be provided to prevent excessive over or under-pressurization of the enclosure”. Cannon Fire will always advise the fitting of negative pressure venting on synthetic agent systems based upon calculations which take into consideration the room strength of the protected area.

The Fire Protection Experts

Have a Question?

Request A Quote

Have a project or portfolio that you would like to work with us on? Get in touch and a member of our team will be in touch very shortly..

Our two head offices are based in Birmingham and Ollerton with fully qualified, experienced engineers spread throughout the UK allowing Cannon Fire to operate nationwide.

Call Us: 01623 860685

Email Us: [email protected]

CONTACT DETAILS

Trading Offices

Unit 1 Sherwood Network Centre, Ollerton, NG22 9FD

Unit C, 37a Parkfield Road, Coleshill,

Birmingham, B46 3LD

OUR KEY SERVICES

Copyright © Cannon 2024 All rights Reserved